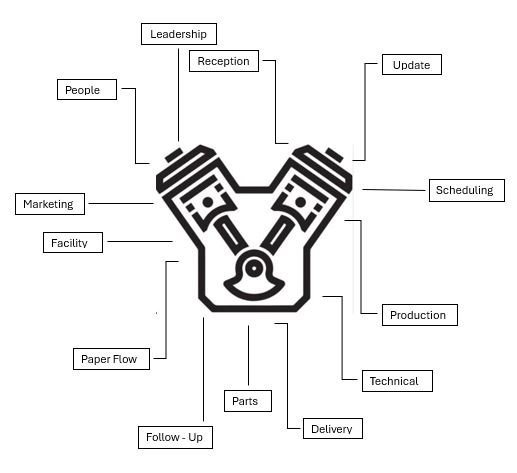

OPERATIONS CHECKLIST

Let’s get started;

FIRST, IS YOUR COMPANY AND IT’S FIXED OPS DEPARTMENT ALIGNED

Is there a clear and documented;

a. Company Mission statement

b. Vision

c. Core Values

- Does every employee know the items above and if asked know how their daily actions connect to the overall success of the company?

SECOND, DO YOU AND YOUR TEAM HAVE OPTICS

- Does the Business Owner and their Senior Management have a dashboard to know how the business is performing right now?

- Do the department heads know their financial objectives and what KPIs are critical to their success?

Now we can start working on the Fixed Ops processes;

SCHEDULING AND APPOINTMENTS

Develop and start regularly using a Secret Shop Form

- Perform a secret shop of your department specifically looking for opportunities in scheduling and appointments. If you call into the store, what is your experience from the customer’s perspective. Are the advisors setting up for the visit, courteous, and most importantly…asking for the appointment?

PERFORM A REPAIR ORDER REVIEW of at least 100 sequentially cashiered customer pay and warranty repair orders

Use a Repair Order grading form

- Perform a repair order review. Look for repair order accuracy, customer information gathering, and documentation of opportunity. Are the notes complete and understanable to a customer? Did the advisors collect information for us to market to a customer’s future needs?

CUSTOMER AND VEHICLE RECEPTION

Use a Reception Observation Form

- Perform an observation of the reception process from the time customer arrives until the repair order is generated and the customer initially leaves the building or walks into the waiting area. Are they setting up the customer’s experience for success? Are they connecting with customers on a deeper level and buidling rapport? Are we working on building life long relationships and addressing future needs or just taking orders?

SHOP PRODUCTION

Use a Production Analysis Spreadsheet

- Perform an observation of the shop from the technician’s perspective. Is the process focused on keeping them in their bay turning wrenches? Are there non-productive activities that someone else could be doing? We suggest documenting some of your production processes and using a stopwatch to find bottlenecks and correct. Identify, Exploit the Constraint, Subordinate, Elevate, Repeat.

TECHNICAL

- Perform an audit of the technical attributes of your shop are. Do the technicians have the right training and the right tools for the type of work being performed? Is it representative of the work mix? If there is a vehicle that they have challenges on, do they put it to the side or is there a way they can get next level guidance? Do you have processes for comebacks?

PARTS INTERACTION AND OPERATION

- Perform an observation of how the parts department interacts with the service department. Are they focused on keeping the technicians working on vehicles in their stalls efficiently and on delivering an exceptional customer experience through the Service Department? Is the inventory being managed efficiently and lost sales being recorded?

UPDATE AND SELLING

- Perform an observation of the process from the moment the repair order makes it back to the advisor from the shop until returned to the technician. Are the advisors maximizing opportunities and giving clarity to the customer in ordr to set proper expectations on pricing and time of completion? Is there a way for us to monitor carryovers and use it to feedback the appointment schedule?

DELIVERY AND CASHIERING

Use a Delivery Observation Form

- Perform an observation of the delivery process from final invoicing until the customer takes their vehicle. Are they getting a clear description of the work performed? Do they clearly understand what they are paying for? Are we setting them up for a successful next visit and making sure we delivered on what we promised from this one?

AFTER SERVICE FOLLOW UP

- Is there a post-service follow-up process that occurs within 48 hours of completion? What is it and how does it help improve the customer’s experience?

PAPER FLOW

- Do repair orders reflect only vehicles on premises? Does paperwork have the ability to move independently of the vehicles progress?

FACILITY SETUP

Use a Facility Inspection Form

Perform an analysis of the facilities. The focus should be on paperflow, vehicle flow, key flow, and technician productivity

*Is the shop optimized for technician efficiency?

*Are the customer areas representative of an exceptional customer experience?

MARKETING

- Is there a marketing plan for the service department? Are the leads we have being maximized for opportunities and potential customers.

PEOPLE

- Perform an inventory of your recruiting, hiring, and onboarding processes. Are you keeping employees engaged? Are you removing poor performers and bad behaviors? Are your hiring processes managing and lowering the risk of making a bad hire?

We also build great Leaders! This journey should be about taking others with us as we teach, grow, and have fun doing it!!!

CONTACT US FOR YOUR COMPLIMENTARY CONSULTATION AND JOIN OUR NEWSLETTER. Also, Check out our ARTICLES page for more helpful information!

LET US Help!

ghull215@gmail.com

818.339.9792